What Goes Around Comes Around - Australian Recycling Week 2023

This post is part of a series where our co-founder Steven Korner will be talking about a range of topics – from design, to what it’s like to engineer a product in the sustainability space.

It’s Australian Recycling Week, and this year's theme is “What goes around, comes around.”

I’ve been thinking about the relevance of this topic; while it can be interpreted as a metaphor for recycling, to me, it's more indicative of the wider issues facing the manufacturing and waste industry – overproduction and short product life cycles. After all, the more we produce, the more creative solutions we need to find for the end-of-life of products.

At the end of the day, recycling is still the ambulance at the bottom of the cliff; it should be the bare minimum for the end-of-life of a product or packaging - not the gold standard. This is something that can be over-simplified about the circular economy; a circular economy isn’t just a system where all materials are recycled back into new products - it's also about extending and maximising the useful life of a product and its materials and taking a life-cycle approach to product design.

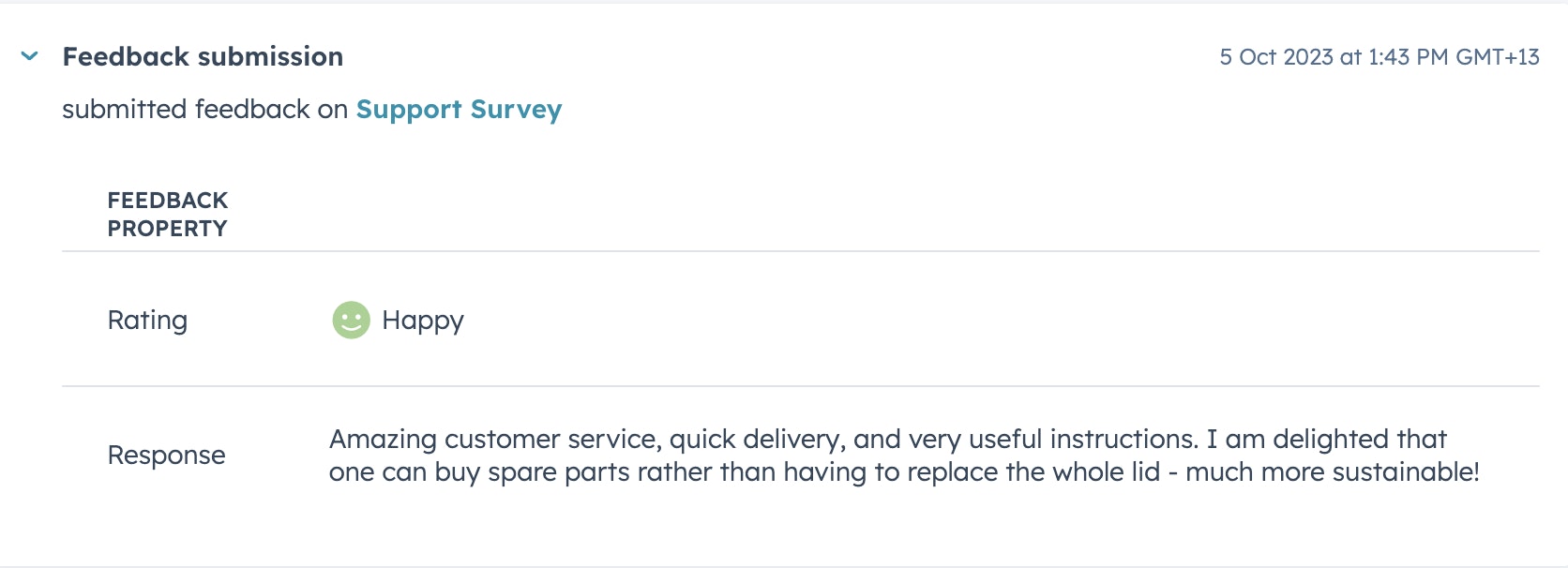

A life-cycle approach is about a product's consequences at all stages of life (intended or not). How it’s designed to be used, how it’s intended to be maintained, if it’s repairable, and the end-of-life. For example, one thing that we constantly hear positive feedback about from customers is the modularity of our bins. The lids of our bins are interchangeable in their respective sizes, e.g., any 60L lid will fit on any 60L base - there is no need to buy an entire new bin if one of your streams needs to be changed due to updated regulations. It’s also always our preference to repair any issues that may occur before replacing. Also, we recommend this to our customers when they ask for a whole new bin.

A real feedback survey from a customer who was outside of warranty

A real feedback survey from a customer who was outside of warranty

I believe a life cycle approach is a big part of what makes businesses prioritising sustainable design successful. It’s about reducing waste at every stage – reducing energy waste, reducing wasted time for people, and reducing manufacturer errors. Ultimately, sustainability is as much about efficiency as anything else - and all businesses aim for operational efficiency. Even if it doesn’t motivate organisations from a sustainability and efficiency perspective, we regulations are catching up that mandate this manufacturer responsibility.

Looking at the EU there are a few key pieces of legislation that manufacturers should be aiming for now to future-proof their product sets. The Right to Repair Bill was introduced in the EU in 2021 requiring manufacturers to have spare parts readily available, for reasonable time frames, for example refrigeration devices for 7 years after purchase. Further, they needed to be repairable with standard tools.

France have taken this a step further, in a bid to combat planned obsolescence, in 2021 they required 4 key product categories to display a Repairability Index. The Repairability Index is a score out of 10 that lets consumers know how repairable a product is. A Repairability Index is now required for washing machines, smartphones, laptops, televisions, electric lawnmowers, dishwashers, vacuum cleaners and high-pressure cleaners. But they’re not stopping there, by 2024 they’re expanding it to a Sustainability Index by including criteria that cover the durability, robustness or reliability of products.

What does this mean for businesses trying to reduce waste this recycling week?

For organisations, this means that waste is largely a question of procurement and supplier standards. Just as we’re asking manufacturers to consider the lifecycle of their products, organisations should consider more than simply price when making purchasing decisions.

We treat things as we value them, and as such, if we invest in things that are in line with our values and make us feel good, we’re going to care for them better. I’m sure we’ve all lost hundreds of generic pens over the years, but the expensive fineline, gel, refillable, fountain pen we splurged on sticks with us for longer because we are motivated to keep tabs on it.

While regulations around the world are starting to require organisations to commit to Extended Producer Responsibility, those who proactively bake a circular life cycle approach into their business are already strides ahead. Organisations as consumers need to continue to support organisations that are committing to a life cycle approach now.

So this recycling week, in addition to ensuring you have the infrastructure and education to collect recyclables, look at your procurement standards and if you’re a manufacturer - start looking into a life cycle assessment for your products.

If you want to learn more about how Method ‘walk the talk’ on product stewardship, you can learn more about our bin-return program here: methodrecycling.com/end-of-life-bin-program.

Profile: Steven Korner

Steven Korner graduated from the University of Canterbury with first-class honours in Mechanical Engineering.

After leading the neonatal care product design team at Fisher and Paykel, and inspired by buying Total Bins, he and his wife India decided to create their own company and their own product.

Steven took an analytical approach with Method – spending weeks researching, prototyping, and gaining customer insights to decipher what could really make a difference in the waste market.

As co-founder and CEO, he has spearheaded Method’s innovative product research, development and design, and is the creator of Method’s award-winning 60L Office Recycling Bin.

Any questions? Get in touch here.